Product traceability and documentation

BM is a constantly evolving company, dedicated to acquiring high and innovative technology in the process of anodizing aluminum.

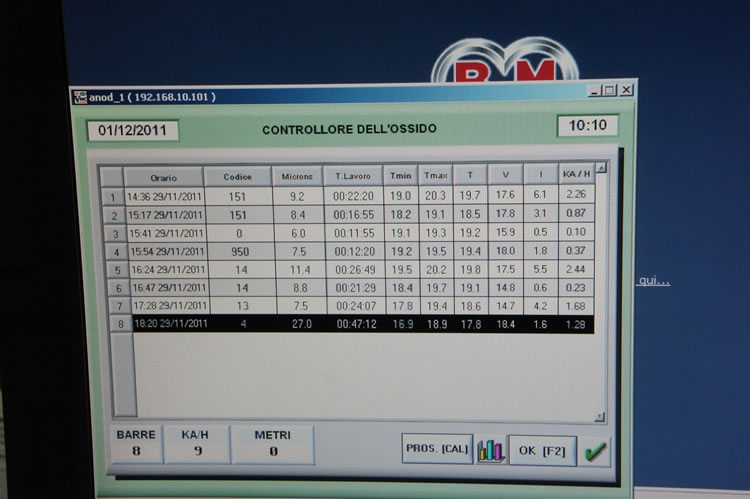

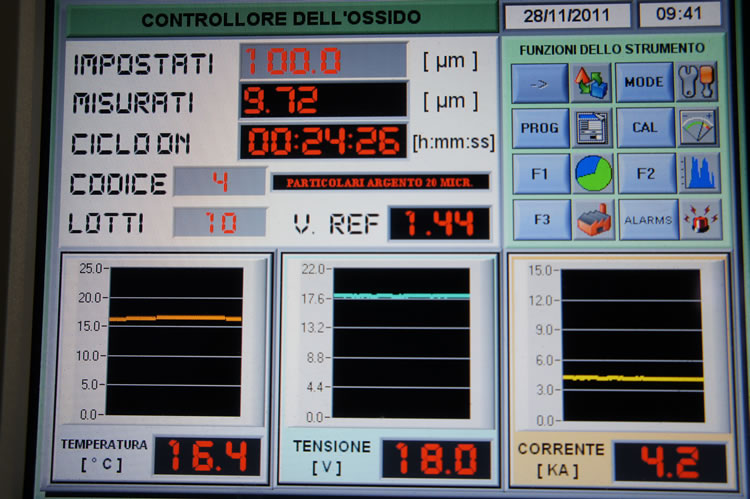

We have the latest technologic systems complete with digital tools for process control in the oxidation tanks and related product traceability.

The main functions of computer systems are the following:

- Estimating the timing of treatments based on the microns set

- Graphically displaying data such as voltage, temperature, microns

- Managing the historic data of each bath with each treatment performed and the option to analyze temperature trends, current density and the acid consumed

- Customized prints of process data for each individual treatment for any certification

- PC connection for remote monitoring;

- Excel database creation

These computerized systems allow us to daily and continuously save all the information regarding the work cycles, in order to have product traceability throughout the whole process of anodizing.

B.M. Group S.R.L. also guarantees the quality and efficiency of the anodizing processing cycle through the daily monitoring of key analytical parameters.