Plants

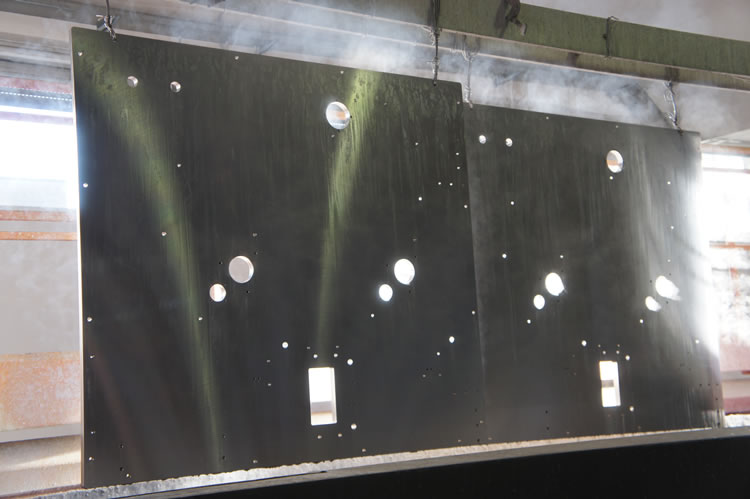

Completely renovated in 2009, the plant is made up of 21 tanks used for the processing cycle – 3 of which are for oxidation – 2 drying ovens – one of which is directly connected to the plant – and 10 loading cart stations. The plant also has a computerized system for the traceability of the production process.

PLANT 1

- Length of tanks mm 7300

- Width of tanks mm 700

- Depth of tanks mm 1500

PLANT 2

- Length of tanks mm 4000

- Width of tanks mm 700

- Depth of tanks mm 2500

All the moving parts work under PLC supervision in order to control the status of the plant during all of its operation cycles, increasing the security of the process.

WORKING SECTORS

Mechanical – Packaging – Electronic – Food – Automotive – Photovoltaic – Lighting – Naval Works – Sheet Metal working – Woodworking – Automation – Architecture – Traffic – Technology – Railway – Die-casting foundries – etc….